Like many other cutting edge and advanced technologies in multiple professions, the construction industry is also progressing with the innovation of technologies and construction methods. BIM, augmented reality, Digital Twins, 4d Simulation and many more like this. Similarly 3d printing is a very amazing technology. In this blogpost, we are going to discuss what is 3d printing, few of its examples and its rising trend in the construction industry.

What is 3D Printing?

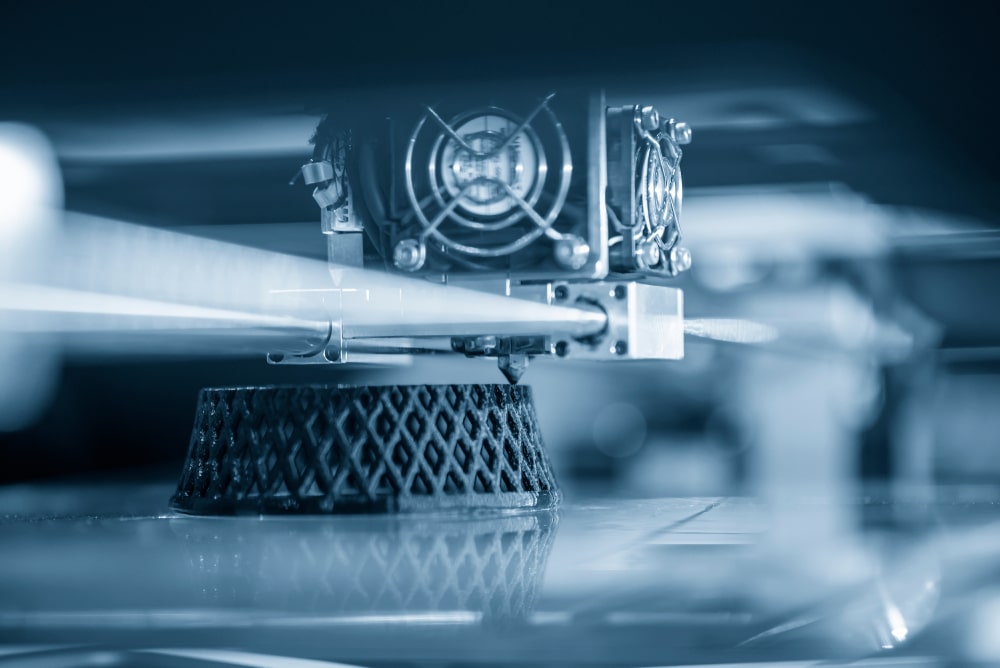

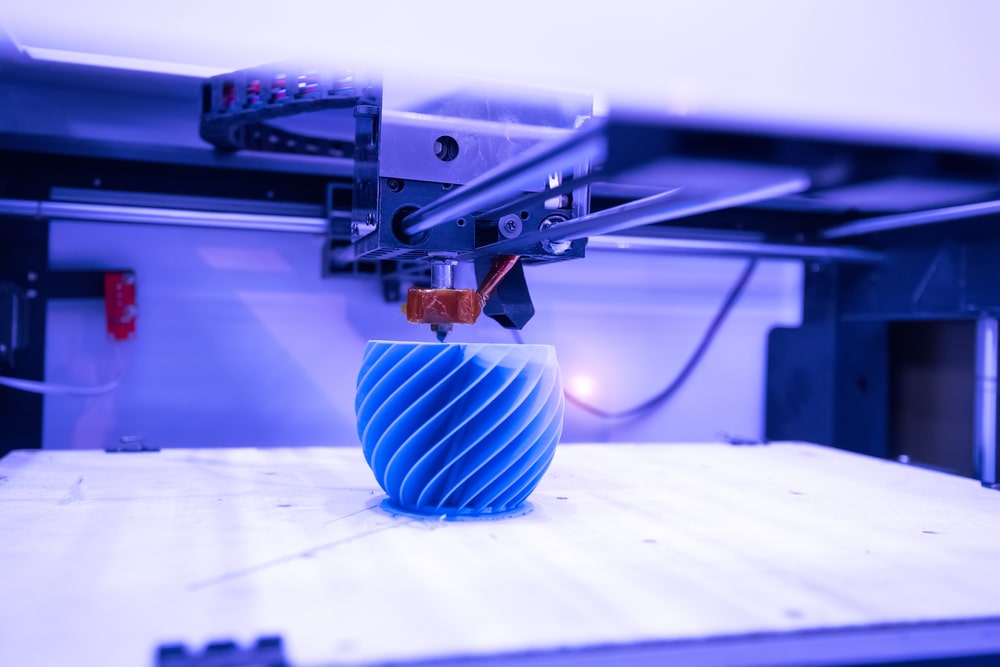

Firstly, let us discuss what is 3D printing. 3D printing is a process of creating three-dimensional objects from digital models. This is done layer by layer using materials like plastic, metal, or even concrete. It’s sometimes called additive manufacturing because it builds up layers instead of carving out from a block like traditional methods.

History of 3D Printing

3D printing has been around longer than most people think. The concept started in the 1980s when Chuck Hull developed stereolithography, the first-ever 3D printing method. Since then, the technology has rapidly advanced, evolving into a powerhouse for innovation across many sectors.

How Does 3D Printing Work?

3D printing works by using a 3D model, usually designed with CAD (Computer-Aided Design) software. The model is sliced into thin layers, which the printer replicates one by one until the object is fully formed. The printing process can differ depending on the type of printer and materials used.

Types of 3D Printers

There are various types of 3D printers. Let us cover some of them

- FDM (Fused Deposition Modeling): Most commonly used for simple and cost-effective printing.

- SLA (Stereolithography): Known for producing high-resolution objects.

- SLS (Selective Laser Sintering): Uses lasers to fuse powdered materials.

Materials Used in 3D Printing

The materials used in 3D printing vary widely, depending on the intended application. Some of the most common materials include plastics like PLA and ABS, metals like titanium and stainless steel, and advanced materials like carbon fiber or biodegradable plastics.

Common 3D Printing Materials

- Plastics: Easy to mold and inexpensive.

- Metals: For industrial applications.

Advanced 3D Printing Materials

- Bio-materials: Used for medical implants.

- Concrete: Now being used in construction projects.

Key Advantages of 3D Printing

The flexibility of 3D printing opens doors to endless possibilities. Some of its key benefits include:

- Customization: Designs can be easily modified. Option of customization is available.

- Speed: Prototyping and production can happen much faster in 3D printing

- Cost-Efficiency: It eliminates the need for large-scale production lines.

Best Examples of 3D Printing in the World

The impact of 3D printing is visible across multiple industries. Here are some standout examples:

Medical Industry

3D printing is revolutionizing healthcare by enabling custom-made prosthetics and implants. Surgeons can now print exact replicas of organs for practice before actual surgery.

Automotive Industry

Car manufacturers are using 3D printing to prototype vehicle parts, speeding up the process of bringing new designs to market.

Fashion Industry

Yes, 3D printing is even in fashion! Designers are creating custom-made jewelry and shoes, pushing the boundaries of creativity.

Aerospace and Aviation

NASA and other organizations are using 3D printing to create lightweight, strong parts for spacecraft. This significantly cuts down on production time and costs.

Food Industry

Believe it or not, 3D printers can print food! Chefs are experimenting with 3D-printed meals, creating intricate designs that are impossible with traditional cooking methods.

What Is 3D Printing’s Role in the Construction Industry?

While 3D printing is already established in industries like healthcare and manufacturing, its role in the construction industry is still emerging. Its usage and potential is massive. Imagine how easy it is building homes, bridges, and entire neighborhoods by printing them layer by layer. This could drastically change how we think about construction.

How 3D Printing is Revolutionizing the Construction Industry

3D printing brings many benefits to the construction industry, including:

Faster Project Completion

Traditional construction projects can take months or even years, but with 3D printing, buildings can be printed in a matter of days. This reduces time spent on labor and project management.

Cost Reduction

Since 3D printing uses only the material required, there’s far less waste. This can significantly reduce overall construction costs, making building more affordable.

Sustainability in Construction

3D printing allows for the use of eco-friendly materials and minimizes waste, which can lead to greener, more sustainable construction practices.

Examples of 3D Printing in the Construction Industry

Several remarkable examples show how 3D printing is already impacting construction:

3D-Printed Houses

In countries like the Netherlands and Dubai, companies are already constructing entire homes with 3D printers. These homes are not just experimental; they’re being built for real-world use, offering affordable housing options.

Bridges and Infrastructure

In China and the Netherlands, 3D-printed bridges have already been successfully installed. These projects are pioneering a future where infrastructure is cheaper and faster to build.

Future of 3D Printing in Construction

The future looks bright for 3D printing in construction. As technology improves and becomes more affordable, we can expect to see 3D-printed skyscrapers, roads, and even entire cities. The potential to revolutionize the way we build is enormous.

Conclusion

It is predictable nowadays that 3D printing is the future of the construction industry. It is more than just a surprising technology; it’s reshaping industries from healthcare to fashion and beyond. In the construction industry, its potential to reduce costs, improve efficiency, and promote sustainability is revolutionary. As 3D printing continues to evolve, the buildings of tomorrow may look very different from those we know today.

FAQ’s

1. How long has 3D printing been around?

3D printing has been around since the 1980s, with Chuck Hull developing the first method in 1984.

2. Can 3D printing be used in mass production?

Yes, but it’s mainly used for prototypes and small-scale production. However, it’s gradually being applied in larger projects, especially in construction.

3. What materials can be 3D printed in construction?

Concrete, metals, and even composite materials can be 3D printed for construction purposes.

4. Is 3D printing eco-friendly?

Yes, 3D printing can be more eco-friendly than traditional methods due to its reduced material waste and use of sustainable resources.

5. What is the biggest limitation of 3D printing in construction?

One of the biggest limitations is the lack of universal building codes for 3D-printed structures, which complicates widespread adoption.