In a world of rapid technological progress, 3D printing has emerged as a game-changer technology, transforming the way we build structures. Imagine a future where entire houses can be constructed in just days, complex architectural designs are brought to life with precision, and construction waste is greatly reduced. This is the power and charm of 3D printing in construction.

As we explore this fascinating technology, we’ll uncover its essence, its evolution in the construction industry, and the exciting prospects it offers for the future of architecture and engineering. This article is all about layers of innovation and creativity, where concrete meets code and imagination turns into tangible reality. In this blog post, we will cover the core concept, benefits, and examples of 3d printing technology in the construction industry.

Core Concept of 3D Printing

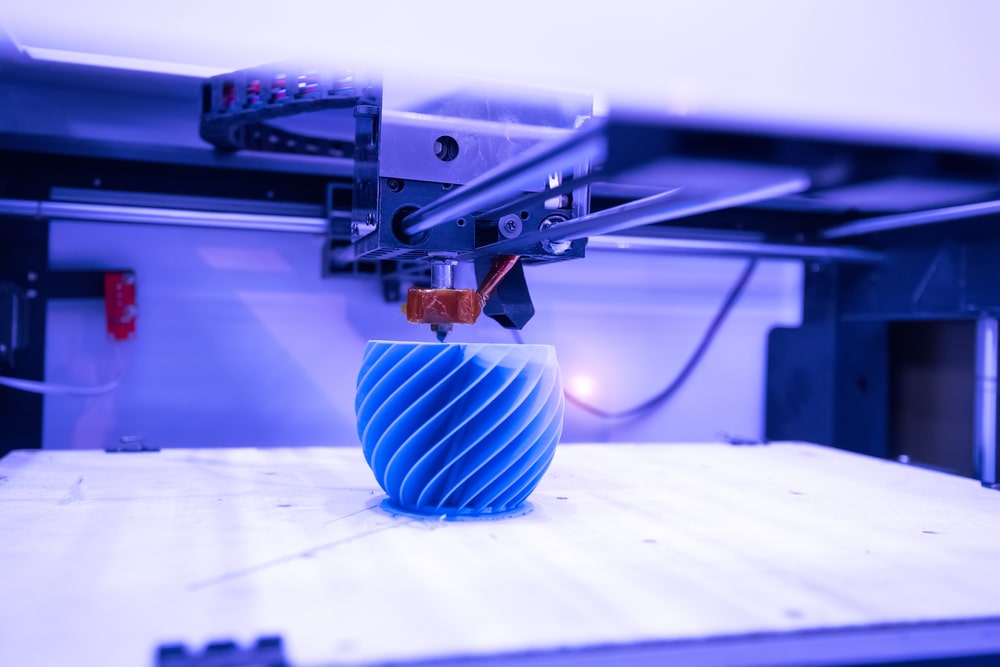

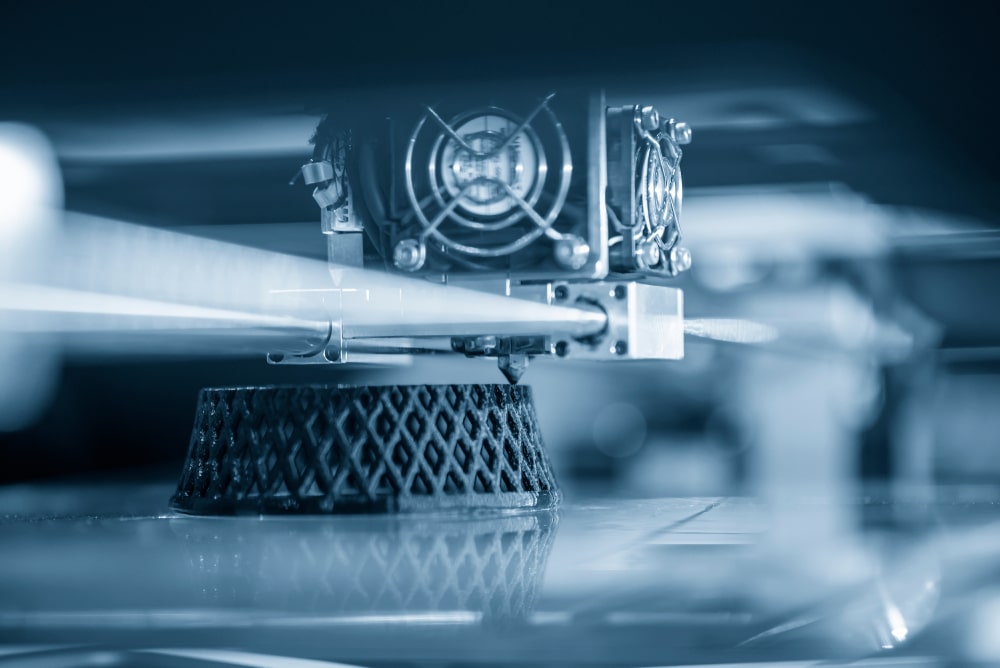

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital model by depositing material layer by layer. While this technology initially found its foothold in the prototyping and manufacturing sectors, its applications in construction have been rapidly expanding.

Traditionally, construction has been a labor-intensive and time-consuming process, often plagued by inefficiencies and cost overruns. However, with 3D printing, the paradigm is shifting. By extruding materials such as concrete, plastic, or even metal layer by layer, intricate structures can be built with unprecedented speed and accuracy.

The evolution of 3D printing in construction has been marked by milestones that showcase its transformative potential. From small-scale prototypes to full-scale buildings, architects and engineers are pushing the boundaries of what’s possible with this technology. Companies like ICON and Contour Crafting are leading the charge, demonstrating the feasibility of printing entire houses in a matter of hours.

Top 6 Benefits of 3D Printing in Construction Industry

Now let us discuss six benefits of this cutting-edge technology in the field of Civil Engineering and Construction Industry.

Cost-Effectiveness

3D printing can reduce construction costs by minimizing material waste and labor expenses. It allows for efficient use of resources, resulting in significant cost savings.

Speed

3D printing enables rapid construction compared to traditional methods. It can drastically reduce project timelines, allowing for faster completion of buildings and infrastructure.

Complexity

3D printing technology allows for the creation of intricate and complex designs that may be difficult or impossible to achieve with traditional construction methods. This opens up new possibilities for architectural creativity and innovation.

Customization

With 3D printing, buildings, and components can be easily customized to meet the specific needs and preferences of clients. This flexibility allows for greater personalization and adaptability in construction projects.

Sustainability

3D printing can contribute to sustainability in construction by minimizing material waste and reducing carbon emissions associated with transportation. It also enables the use of eco-friendly materials and construction techniques.

Accessibility

3D printing technology makes construction more accessible to communities in remote or underserved areas. It can be deployed quickly and efficiently, providing affordable housing solutions and infrastructure where needed most.

These benefits demonstrate the potential of 3D printing to revolutionize the construction industry, offering improved efficiency, creativity, and sustainability in building projects.

Examples of 3D Printed Buildings

Now, we discuss some of the real examples of 3d printed buildings in the world.

Apis Cor House, Russia

The Apis Cor project in Stupino, Russia, saw the construction of a 3D-printed house in just 1 Day (24-Hours). The house featured a curved design and was printed using a mobile 3D printer on-site.

TECLA, Italy

TECLA is a prototype for sustainable housing created using a 3D-printing technique called “Crane WASP.” This eco-friendly house was built using locally sourced raw earth materials and is designed to blend with its natural surroundings.

Dubai’s Office of the Future, UAE

Dubai’s Office of the Future is the world’s first 3D-printed office building. Constructed using a 20-foot tall 3D printer, this futuristic office showcases Dubai’s commitment to innovation in construction technology.

Vulcan Pavilion, China

Located in Beijing, China, the Vulcan Pavilion is a stunning example of 3D-printed architecture. This structure was created using a robotic 3D printer and features a unique design inspired by traditional Chinese culture.

Mars Habitat, USA

While not yet constructed on Mars, NASA’s Mars Habitat prototype serves as a demonstration of 3D printing’s potential for extraterrestrial construction. This habitat was 3D printed using materials simulating Martian soil and is designed to provide shelter for future astronauts on the Red Planet. This will be a future marvelous construction.

FAQs (Frequently Asked Questions)

1. How does 3D printing in construction work?

Ans. 3D printing in construction involves using large-scale printers to deposit construction materials layer by layer, following a digital blueprint of the desired structure.

2. What materials are used in 3D printing for construction?

Ans. Common materials include concrete, polymers, and composites, although researchers are exploring the use of sustainable alternatives such as recycled plastics and bio-based materials.

3. What are the advantages of 3D printing in construction?

Ans. Some advantages include reduced construction time, lower costs, enhanced design flexibility, and the potential for reduced environmental impact through minimized waste.

4. Are there any limitations to 3D printing in construction?

Ans. Challenges include scalability, regulatory hurdles, material limitations, and the need for skilled operators to oversee the printing process.

5. Is 3D printing in construction economically viable?

Ans. While initial costs may be higher, the long-term benefits in terms of efficiency, reduced labor costs, and minimized waste can make 3D printing a compelling option for certain projects.

6. What are the implications of 3D printing for architectural design?

Ans. 3D printing enables architects to explore complex geometries and innovative designs that were previously difficult or impossible to realize using traditional construction methods.

Also read about other advanced technologies in the construction field.

- How Blockchain Technology Can Transform the Construction Industry

- Green Building Construction Technology and its Types and Benefits

- Drones in Construction Industry 2024: Uses Benefits and Applications

Conclusion

In conclusion, the evolution of 3D printing technology is reshaping the landscape of the construction industry, offering a glimpse into a future where buildings are not just erected but constructed with precision and perfection. Consider the story of the “Apis Cor” project, where a 3D-printed house was constructed in just 24 hours, showcasing the remarkable capabilities of this technology. This amazing accomplishment shows the potential of this technology and how much 3D printing can do, not just for buildings but in shaping communities and improving lives. As we use this technology more, we’re heading towards a future where we can make anything we imagine with just a click.